THANK YOU FOR SUBSCRIBING

By Michelle Brydalski, Vice President, Food Safety, Quality Assurance, Charcuterie Artisans

Listeria Control in a Ready to Eat (RTE) Environments

By Guillaume Couture, Quality Director, Kerry Inc.

Guillaume Couture: Safeguarding Quality and Safety in the...

By Enrique Leon, AI Enterprise Architect, American Sugar Refining Inc

Enhanced Precision Agriculture using Cloud Based AI

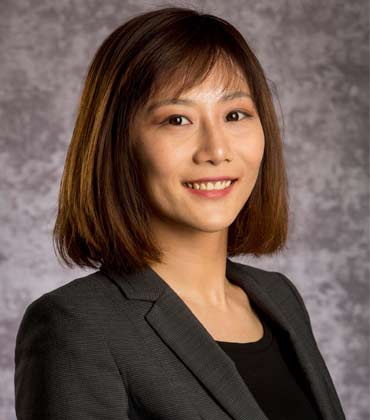

By Ruohan Liu, Senior Director, Global Operations, Agriculture Supply Innovation, PepsiCo

How Cloud Computing Impacts Precision Agriculture Technology

The Micro Revolution In the U.S.

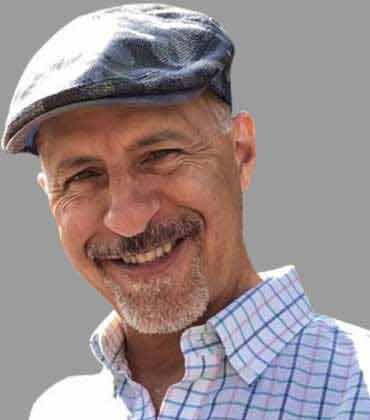

Juan F. DeVillena, Sr. Vice President of Quality Assurance and Food Safety at Wayne-Sanderson Farms

Juan F. DeVillena, Sr. Vice President of Quality Assurance and Food Safety at Wayne-Sanderson Farms

Juan F. DeVillena, Sr. Vice President of Quality Assurance and Food Safety at Wayne-Sanderson FarmsWhen I arrived in the U.S. in July of 1999, little did I know I would be immersed in a micro-adventure. While pursuing my degree in Food Science at the University of Maryland, I was introduced to food safety research. Dr. Jianghong Meng conducted research on retail meats to identify the prevalence of E. coli (generic), Salmonella, and a new bacteria I had heard of before but was not familiar with —Campylobacter spp. I found food safety research simply fascinating, as well as conducting research at the Food and Drug Administration -Center for Veterinary Medicine.

With my research and thesis focused on the fluroquinolone resistance of avian E. coli from North Georgia, it was natural that my interest would focus on the poultry industry. When I started my first job in the industry in 2002, I realized that all my microbiology, research, and food processing knowledge came in handy. I was working for a very efficient team with the same objective, producing safe poultry products to feed, literally, the world. Our ‘enemy’ was E. coli and Salmonella. We didn't talk about Campylobacter spp., as nobody did at that time.

With innovation, we devised strategies to reduce the prevalence of Salmonella— a naturally occurring and colonizing bacteria in poultry. We used science and controlled Salmonella with physical interventions, adjusting the pH of solutions, adjusting the temperature during the process and the media, ensuring First In, First Out (FIFO) food storage, as well as being conscious about shelf-life and the fact that we work with a perishable product.

At the time, the United States Department of Agriculture Food Safety and Inspection Service (FSIS) had a 13-rolling window for E. Coli level (CFU/ml) with marginal ‘m’ results (100 CFU/ml) and unacceptable ‘M’ results (≥ 1,000 CFU/ml) and a 51-consecutive day rolling window for Salmonella prevalence (%) with a maximum allowable of 12/51 samples. I can’t even tell you how many Salmonella ‘windows’ I have been involved in. All of them were completed successfully and without further action.

By 2004, I started working with an amazing company, and FSIS changes in the regulatory framework were full on board with new water retention statements on packages, the HACCP based inspection model project (HIMP), new interventions, and new technologies (e.g., only-line reprocessing) becoming the new norm. A couple of years later, the FSIS announced the implementation of Salmonella categories (Category 1: 0-6, Category 2: 7-12, and Category 3: >12 out of 51 consecutive samples collected –for prevalence) for poultry establishments, which were based on the Salmonella rolling window results for whole birds (W.B.).

"With innovation, we devised strategies to reduce the prevalence of Salmonella— a naturally occurring and colonizing bacteria in poultry"

As the poultry industry improved and drastically reduced the prevalence of Salmonella, a new prevalence standard was announced in 2011: 5/51, with Categories changing to Category 1: 0-2, Category 2: 3-5, and Category 3: >5 out of 52 consecutive samples collected – prevalence for W.B. and now a Campylobacter performance standard was announced for W.B. (8/51). By now, nobody talked about E. coli (generic) as an indicator organism. Instead, E.B. and APC were now the newcomer indicators. Then, in 2016, the introduction to Parts performance standards: 8/51 for Salmonella and 4/52 for Campylobacter came into reality with a 52 weekly rolling window.

Shifting over to processing, in 2017, the FSIS announced the New Poultry Inspection System (NPIS), to which interested plants had to apply through a rigorous application process.

After one year in NPIS, approved establishments could apply to a line speed waiver program, which also required a rigorous application process and data sharing. A little over 50 establishments in the U.S. were approved to run at higher evisceration line speeds (≥140 birds per minute).

By the end of 2017, the FSIS announced the posting of W.B. Salmonella categories on their website and, as of 2018, the posting of Salmonella Parts categories as well. A change of Campylobacter Good Laboratory Practices (GLP) would occur the same year, by which Campylobacter isolates would be enriched prior to prevalence testing.

Of course, then, in 2020, the Coronavirus pandemic reached the U.S., and literally our lives were changed forever. By September 2020, Dr. Mindy Brashears, while she was the Under Secretary of Agriculture for U.S. Food Safety, introduced the ‘Roadmap to Reducing Salmonella,’ a driving change through science-based policy.

By the following year, in 2022, the FSIS held two Industry Roundtable [virtual] meetings, discussing the future of Salmonella control in Poultry: Pilot Projects. The same year, in August, FSIS proposed to declare Salmonella as an adulterant in stuffed and breaded chicken products, which was announced during the IAFP meeting in Pittsburg, Pennsylvania.

Almost at the same time, the new modified Line Speed Waiver was introduced to all original Line Speed Waiver holders as a new program to apply for, along with sharing monthly worker safety data with FSIS. To finish up the year with flying colors, FSIS introduced the Proposed Regulatory Framework to Reduce Salmonella Illness Attributable to Poultry, which included three components: incoming flock testing, enhancing establishments process control, and implementing an enforceable final product standard. As described, we have experienced several changes, specifically in regulatory requirements, which the poultry industry has proactively embraced and adapted.

Read Also